Apparel & Fashion: Managing Peak Season FCL Shipments Efficiently

Peak season is one of the most challenging periods for the apparel and fashion industry. Every year, demand surges during festivals, holidays, back-to-school periods, and new seasonal launches. Fashion brands must move bulk inventory quickly, stay ahead of sales timelines, and keep shelves stocked across global markets.

On top of that, fashion trends change fast. Retailers cannot afford delays, stockouts, or mismanaged shipments. This is why FCL (Full Container Load) shipping becomes a preferred choice for moving apparel during high-demand periods.

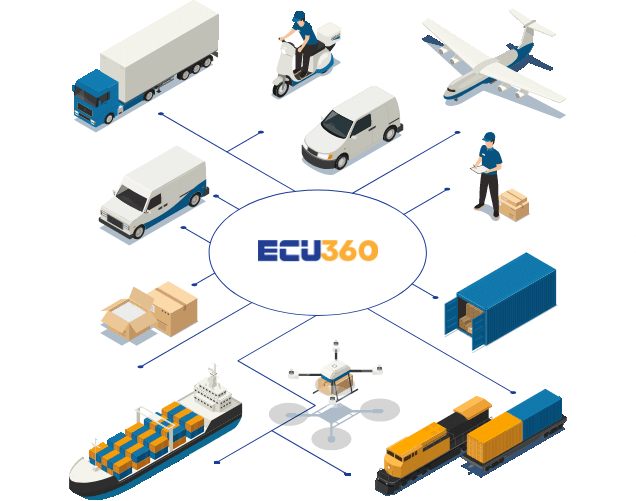

This article explores how apparel brands can manage peak season FCL shipments efficiently and how ECU 360 supports them with organized booking, transparent pricing, and smooth port-to-port logistics.

1. Why Peak Season Challenges the Apparel Supply Chain

The apparel industry experiences some of the most intense seasonal fluctuations. Peak seasons include:

- Black Friday and Cyber Monday

- Christmas and year-end sales

- Summer and winter collection launches

- Eid, Diwali, and Lunar New Year

- Back-to-school demand

- Fashion week releases

During these periods, supply chains face heavy pressure because:

- Order volumes rise drastically

- Production timelines tighten

- Warehouse space becomes limited

- Global shipping demand spikes

- Freight rates fluctuate

- Ports experience congestion

To keep the business running smoothly, fashion brands must plan their logistics early and choose the most reliable shipping method.

2. Why FCL Shipping Is Ideal for the Fashion Industry During Peak Season

FCL shipping offers several advantages over LCL or air freight, especially during peak season.

- Faster movement of bulk inventory

Fashion brands often ship thousands of units at once. FCL provides a dedicated container—no waiting for consolidation. - Better control over timelines

A sealed container reduces handling, leading to fewer delays. - Predictable freight costs

FCL pricing remains more stable than LCL during high-demand periods. - Improved product protection

Garments, fabrics, and accessories remain untouched inside the sealed container. - Ideal for large retail chains

Brands supplying multiple stores or warehouses can load products in pre-sorted batches inside the same container.

These advantages make FCL the preferred approach for peak season apparel logistics.

3. Common Peak Season Shipping Problems for Apparel Brands

Even with strong demand, apparel companies face several challenges:

- Space shortages

During peak season, carriers run full, making it difficult to secure a container at the last minute. - Sharp price increases

Freight rates increase due to global demand, affecting profit margins. - Tight production deadlines

Fashion items must reach shelves before the season starts—any delay causes loss of sales. - Port congestion

Peak season causes longer waiting times at major ports. - Warehouse overload

High incoming volumes make it harder to manage inventory efficiently. - Documentation errors

Incorrect documents can lead to customs delays, which becomes costly during peak season.

To overcome these challenges, fashion brands need strong planning and execution.

4. How Apparel Companies Can Prepare for Peak Season FCL Shipments

- Forecast demand early

Accurate forecasting helps determine:- Number of containers needed

- Production timeline

- Warehouse preparation

- Budget planning

- Book containers in advance

During peak season, FCL space fills quickly. Early booking ensures:- Better rates

- Guaranteed availability

- More sailing options

ECU 360 makes this process easier by providing quick access to schedules and availability.

- Use efficient packing strategiesGood packing reduces wasted space inside the container.

Examples:- Flat-packed apparel to maximize capacity

- Pre-labelled cartons for smoother unloading

- Size-sorted packaging for faster inventory management

- Choose the right container typeDepending on the item, brands may need:

- 20ft for smaller batches

- 40ft for large seasonal stock

- 40ft High Cube for lightweight but bulky garments

- Plan documentation carefullyPeak season leaves no room for errors.

Ensure:- Packing list accuracy

- Correct HS codes

- Timely submission of shipping instructions

- Clear commercial invoices

ECU 360 supports shippers by making documentation easier to manage in an organized, central place.

5. Managing Peak Season Logistics with ECU 360

Fashion companies benefit greatly when FCL planning is structured and transparent. ECU 360 helps businesses stay prepared with practical features that support peak-season operations.

- Real-time access to vessel schedulesFashion brands can compare:

- ETD (Expected Time of Departure)

- ETA (Expected Time of Arrival)

- Transit times

- Carrier options

This helps brands match production timelines with shipping windows.

- Transparent FCL pricingPeak season brings freight cost volatility.

ECU 360 helps shippers manage freight cost planning by showing:- Base ocean rates

- Seasonal surcharges

- Port fees

- Additional charges

Clear pricing helps brands budget better and avoid surprises.

- Quick and organized bookingInstead of waiting for long email chains, fashion brands can book shipments easily and focus more on production and sales.

Early booking reduces the risk of space shortages. - Streamlined documentation workflowThe apparel industry deals with high-volume shipments and multiple SKUs, which means more paperwork.ECU 360 makes document handling easier, reducing the chance of errors that can cause delays.

- Real-time shipment trackingBrands can track:

- Container departure

- Vessel progress

- Port arrival

- Availability for pickup

This allows better planning for warehouse and distribution teams ahead of container arrival.

6. Strategies to Reduce Peak Season FCL Costs

Fashion brands can reduce peak-season freight expenses through smart planning.

- Consolidate orders early

Instead of several small shipments, plan one full container at a time. - Avoid last-minute loads

Last-minute bookings face the highest rates. - Use optimized packing methods

Efficient packing reduces unused space inside the container. - Plan warehouse operations in sync with shipping

Smooth coordination helps avoid demurrage and detention charges at destination ports. - Track freight market trends

Understanding seasonal price patterns helps decision-makers book at the right time.

ECU 360 supports this by giving visibility into available schedules and pricing changes.

7. Improving Warehouse and Distribution Planning During Peak Season

Once FCL shipments arrive, the warehouse must be ready to handle the incoming load.

- Pre-allocate storage space

This avoids congestion and speeds up unloading. - Organize teams for quick turnaround

Seasonal freight volume requires additional hands-on support. - Sync inbound schedules with outbound demand

Garments often need to move fast—sometimes directly from container to retail outlets. - Use carton-level labeling

Labels reduce sorting time dramatically. - Coordinate with local transport ahead of time

Trucking delays can cause congestion and storage fees.

With the visibility provided by ECU 360, warehouse teams can prepare more accurately for container arrival.

8. Why Fashion Brands Prefer ECU 360 for Peak Season FCL Management

Businesses in the apparel and fashion industry choose ECU 360 because it provides:

- Clear and predictable FCL scheduling

- Smooth and fast booking process

- Fully visible pricing

- Centralized documentation

- Real-time container tracking

- Reliable port-to-port logistics

- Strong support for time-sensitive shipments

These features allow brands to maintain stable supply chains even during their busiest seasons.

Conclusion

Peak season is demanding for the apparel and fashion industry. With rising demand, fast-changing trends, and strict delivery deadlines, brands need reliable and efficient logistics solutions.

FCL shipping remains the most practical option for bulk garment movement. By planning early, optimizing container loading, and managing documentation correctly, companies can avoid delays and unnecessary costs.

With the structured workflow, transparent pricing, and reliable visibility offered by ECU 360, fashion brands can ship confidently during peak seasons and maintain a smooth, scalable supply chain from factory to warehouse to retail shelves.

Like

Comments