How Apparel Brands Can Streamline Logistics for Faster Delivery & Lower Costs

For apparel brands competing in the ecommerce space, speed and efficiency are everything. Customers expect rapid delivery, easy returns, and consistent availability — all while brands face rising shipping and fulfillment costs. Balancing these demands requires a logistics model built for agility, visibility, and cost control.

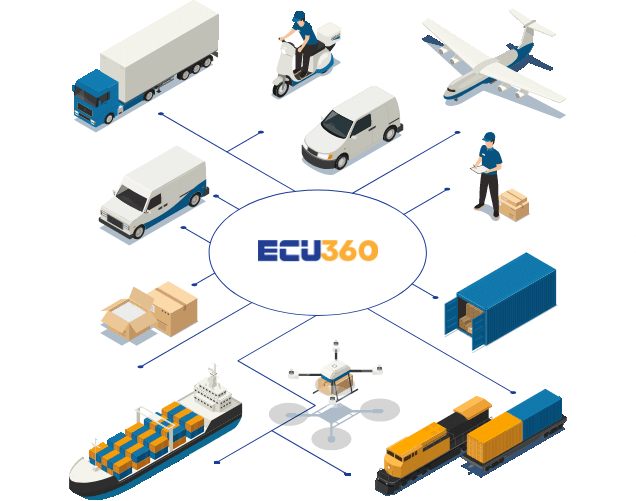

At ECU 360, we help apparel brands modernize fulfillment operations through technology-driven logistics optimization. This guide explores how apparel companies can streamline their ecommerce supply chain for faster delivery and sustainable growth.

1. The Logistics Challenge in Apparel Ecommerce

Apparel logistics is uniquely complex. With multiple SKUs, frequent seasonal launches, and high return rates, managing fulfillment efficiently can be a struggle. The key is to build a supply chain that adapts — one capable of handling demand surges, reducing waste, and delivering products quickly.

Common challenges include:

- Slow or fragmented order fulfillment workflows

- Poor inventory visibility across multiple channels

- Inefficient last-mile delivery routes

- High shipping and return costs

- Lack of real-time data integration between systems

Overcoming these issues starts with streamlining every layer of logistics — from warehouse management to shipping automation.

2. Strengthen Warehouse Management Systems

Warehouse operations form the backbone of apparel fulfillment. Delays or inaccuracies here directly impact delivery times and customer satisfaction.

Key improvement areas:

- Smart storage design: Organize inventory by category, size, or season for faster picking.

- Barcode and RFID tracking: Improve inventory accuracy and reduce human error.

- Batch picking and packing: Increase throughput during peak order periods.

- Automated replenishment: Prevent stockouts and excess inventory simultaneously.

ECU 360’s warehouse management systems (WMS) integrate seamlessly with ecommerce platforms, ensuring apparel brands maintain real-time visibility and fulfillment precision.

3. Optimize Order Fulfillment for Speed and Accuracy

Fast delivery begins with efficient order fulfillment. Apparel brands can reduce order-to-dispatch time by automating key steps:

- Centralized order management: Sync all channels — website, marketplace, or app — to one platform.

- AI-driven order routing: Assign orders to the nearest fulfillment center automatically.

- Automated quality checks: Ensure items meet standards before shipment.

- Real-time tracking: Provide instant visibility for both teams and customers.

ECU 360’s fulfillment automation eliminates manual bottlenecks, enabling apparel brands to process higher order volumes with accuracy and speed.

4. Reduce Shipping Costs Through Smart Logistics Planning

Shipping costs are often the largest operational expense for apparel ecommerce. Reducing them requires strategic planning, data-driven decisions, and the right partners.

Cost-saving strategies:

- Compare carrier rates regularly to find the most competitive pricing.

- Use multi-carrier shipping automation to select the best route and service automatically.

- Consolidate shipments by zone to reduce last-mile costs.

- Negotiate volume-based discounts with carriers using predictive analytics.

ECU 360’s multi-carrier optimization engine automatically identifies the most cost-effective and reliable shipping options — ensuring brands don’t overspend while meeting delivery commitments.

5. Improve Inventory Management Across Channels

Inefficient inventory control leads to split shipments, increased costs, and slower fulfillment. Centralized inventory visibility is critical for efficiency and speed.

Best practices include:

- Real-time inventory synchronization across all platforms.

- Demand forecasting tools that predict best-selling SKUs and reduce overstocking.

- Automated stock transfers between warehouses to balance availability.

- Analytics dashboards to track stock aging and sell-through rates.

With ECU 360’s integrated inventory management system, apparel brands gain data-backed control over stock, reducing delays and improving delivery consistency.

6. Streamline Last-Mile Delivery

The last mile is often the most expensive and time-sensitive part of fulfillment. Apparel brands can cut both cost and delivery time with better route optimization and delivery options.

Tactics for efficiency:

- Use regional warehouses to minimize distance to customers.

- Partner with local couriers for urban deliveries.

- Offer tiered delivery options (same-day, next-day, standard) to balance cost and speed.

- Provide live delivery tracking to reduce failed delivery attempts.

ECU 360’s logistics network supports last-mile optimization through real-time route planning and automated delivery updates, ensuring apparel shipments reach customers faster and at lower cost.

7. Automate Shipping Operations

Manual shipping processes slow down growth and invite errors. Automation enhances consistency, reduces handling time, and provides transparency.

With ECU 360’s shipping automation technology, apparel brands can:

- Automatically generate shipping labels and documentation.

- Assign carriers and routes based on speed, location, and price.

- Track all shipments from a single dashboard.

- Gain insights into delivery performance and carrier efficiency.

Automation not only speeds up fulfillment but also builds a reliable system that scales as order volumes increase.

8. Optimize Returns and Reverse Logistics

Returns are a natural part of apparel ecommerce — but poorly managed returns increase costs and delay restocking. A streamlined reverse logistics process helps brands recover value quickly.

Recommended practices:

- Use regional return hubs to shorten return transit time.

- Offer easy online return portals for better customer experience.

- Refurbish and restock items quickly to minimize loss.

- Analyze return reasons to improve product quality and fit accuracy.

ECU 360 simplifies returns management through localized fulfillment and automated processing, helping apparel brands reduce costs and turnaround times.

9. Enable Scalable, Technology-Driven Logistics

As apparel brands expand, logistics must scale seamlessly to handle larger order volumes, new markets, and changing delivery expectations. Scalability depends on technology integration and flexible infrastructure.

With ECU 360, brands can:

- Scale fulfillment across multiple warehouses effortlessly.

- Integrate ERP, OMS, and WMS systems for unified data flow.

- Access on-demand analytics for operational decision-making.

- Adjust shipping workflows dynamically based on real-time performance.

This connected ecosystem ensures brands maintain agility as they grow — without losing control over cost or customer experience.

10. Partner with an Experienced Fulfillment Provider

Apparel brands grow fastest when they focus on creativity and customer engagement — not logistics challenges. Partnering with a fulfillment expert like ECU 360 allows internal teams to focus on brand-building while the logistics are handled end-to-end.

ECU 360 offers:

- Integrated ecommerce fulfillment solutions across multiple channels.

- Warehouse and inventory optimization for improved efficiency.

- Shipping automation for cost and time savings.

- Last-mile management to ensure reliable and fast delivery.

Our scalable infrastructure and advanced analytics help apparel brands achieve consistent fulfillment performance at lower costs.

11. Build a Sustainable Logistics Model

Sustainability and cost efficiency increasingly go hand in hand. Optimizing routes, reducing packaging waste, and using eco-friendly materials not only cut emissions but also minimize unnecessary expenses.

ECU 360 supports green logistics through:

- Carbon-conscious delivery planning.

- Reusable and lightweight packaging.

- Consolidated shipments to reduce transportation frequency.

- Energy-efficient warehouse operations.

Building sustainability into logistics strengthens both brand reputation and operational resilience.

Conclusion

For apparel brands, logistics is not just an operational necessity — it’s a competitive differentiator. By embracing automation, strategic warehousing, and data-driven decision-making, brands can achieve faster delivery, lower costs, and higher customer satisfaction.

ECU 360 enables this transformation through integrated logistics solutions designed for modern apparel ecommerce. From intelligent order routing to optimized last-mile delivery, we help brands scale smarter, deliver faster, and grow profitably.

Ready to streamline your apparel logistics?

Partner with ECU 360 — your trusted fulfillment and supply chain optimization partner for faster, cost-efficient ecommerce growth.

Like

Comments