4 Recommendations to increase warehouse staff productivity

The majority of warehouse operations are constantly working to increase efficiency by streamlining workflows, automating procedures, and cutting waste (both time and resources). Although there are many strategies to increase warehouse staff productivity, it’s not always clear where your efforts will be fruitful because warehouses are complicated processes with many moving elements and tasks occurring at once.

Logistics technology advancements such as automated robots, as well as innovative AI and machine learning solutions, sophisticated warehouse management software, and other technology solutions, have a significant impact on warehouse productivity. Examining your current processes and systems to identify bottlenecks and other issues, implementing process improvements, and making smart technology investments to address your key challenges puts warehouse organization and productivity within reach.

Adopt lean operations techniques for warehouse staff productivity

From its historical beginnings as the straightforward storage of commodities, warehousing has greatly evolved. High-level inventory management, quick receiving and shipping dock management, and precise, adaptable pick and pack services are now more crucial than ever in a market that is becoming more globally interconnected.

Lean warehouse operations make it possible to save a lot of money in a number of areas over the long run and sustainably. Lean causes a fundamental shift in the mindset of warehouse workers, resulting in decreased handling times, quicker loading and unloading of trucks and containers, enhanced information exchange and reliability, and greater adaptability to changing market conditions and client requirements. Improved picking and packaging procedures reduce the amount of time spent searching for or verifying inventory, make stock replenishment quick and precise, and reduce the number of missed sales chances.

Provide rigorous training for employees

If your staff don’t grasp your technology and processes, even the most effective ones are worthless. Implement comprehensive training sessions that concentrate on technology and how you want your employees to use the resources you’ve provided. Prioritizing safety and fostering creativity should be goals of education and training.

Implement specialized kitting techniques

Custom kitting tactics are the greatest approach to boost warehouse productivity. Reduce inventory handling time and make better use of warehouse storage space by grouping and bagging frequently used parts into tailored kits. Custom kitting can reduce time-consuming mistakes and improve inventory management under pressure for companies that frequently carry out the same kinds of repairs and procedures.

Make workstations organized

Efficiency and mess go against each other. Meaning that workers are more productive when they spend less time looking for the right equipment to do their jobs. Workstation arrangement can help you achieve organizational objectives and cut down on errors.

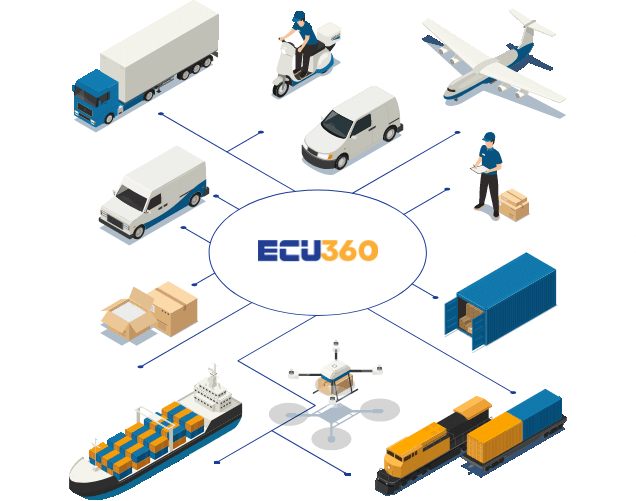

Work System at ECU360

The Freight services we avail to our clients as a customer centric organization our staff also delivers us a good quality of output by being efficiently productive. We at ECU360 provide all our staff members the best quality of practices and trainings especially in terms of technology in order to ensure their growth rate and work proficiency.

Frequently Asked Questions

How do warehouse workers measure performance?

1] Received volume per man-hour

2] Cycle time is the amount of time it takes to process each receipt.

3] Percentage of correct receipts (quality)

4] The percentage or utilization of receiving dock doors.

5] Receiving cost per line (cost metric)

What are major barriers for warehouse productivity?

1] Failure to obtain the appropriate data at the appropriate time

2] We live in a world where data is everywhere and easily accessible

3] Scarcity of resources

4] Space constraints

5] Complete visibility of the supply chain from beginning to end

6] Industry adaptation Technology 4.0

Like

Comments