FCL Shipping in the Food & Beverage Sector: Challenges and Solutions

The food and beverage (F&B) industry is one of the most demanding sectors in global trade. Every shipment must maintain freshness, follow strict health standards, and arrive on time. Because food products are sensitive, often perishable, and usually transported in large quantities, many businesses prefer Full Container Load (FCL) shipping for their international logistics.

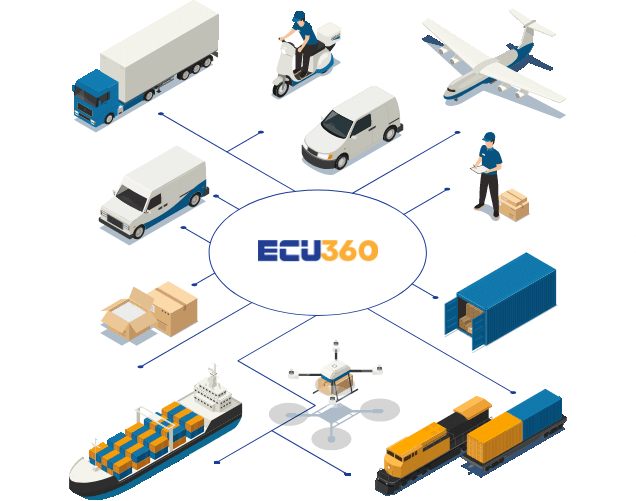

Managing the full process — from booking a container to tracking its movement — becomes much easier when handled through a unified digital platform. ECU360 plays an important role here by simplifying FCL booking, documentation, rate visibility, and container tracking for food and beverage exporters. With the help of digital tools, companies can reduce delays, improve compliance, and protect product quality throughout the supply chain.

Below is a detailed look at the major challenges food and beverage companies face in FCL shipping and the practical solutions that help ensure smooth and safe transport.

1. Why FCL Shipping Is Ideal for the Food & Beverage Sector

Businesses in the food and beverage sector choose FCL shipping for several reasons, all of which support safety, efficiency, and cost control.

- Full control over the cargo space

When a container is not shared, the shipper can set specific conditions required for their products. Through ECU360, shippers can select the correct container type — such as reefer containers for chilled or frozen goods — and review sailing options that fit their cargo requirements. - Lower contamination risk

FCL reduces the chance of contamination since only one shipper uses the container. This is especially important for products like juices, dairy, spices, packaged foods, and frozen items. ECU360 ensures that the allocated containers meet food-grade requirements. - Better cost efficiency for bulk loads

If a company is shipping large volumes, FCL becomes the most cost-effective method. ECU360 provides transparent FCL rates and helps exporters compare options to plan their budgets efficiently. - Stronger compliance and documentation accuracy

Food shipments require health certificates, temperature logs, packing lists, and more. ECU360 helps manage all documents digitally, reducing errors and delays at the port.

2. Key Challenges in FCL Shipping for Food & Beverage Companies

Although FCL shipping offers many advantages, the food and beverage sector faces unique challenges due to product sensitivity and regulatory requirements.

- Challenge 1: Maintaining Cold Chain Temperature

Most food products require continuous temperature control. Even a small fluctuation can cause spoilage or reduce shelf life.

Cold chain challenges include:- incorrect reefer settings

- power interruptions during handling

- slow container movement

- temperature variations during loading

- delays in customs or transshipment

Using ECU360, shippers can plan transit days, select suitable containers, and track shipment progress to maintain better control over their cold chain.

- Challenge 2: Handling Short Shelf-Life Products

Food items such as dairy, fresh vegetables, fruits, meats, and beverages are time-sensitive. Any unexpected delay becomes costly.Common delay points include:- port congestion

- missing documents

- vessel schedule changes

- long customs queues

- slow stuffing or unloading

ECU360 helps reduce the impact of delays by offering real-time updates, booking management, and alerts for important milestones.

- Challenge 3: Meeting Global Food Safety Regulations

Different countries have strict rules for food imports and exports. Missing or inaccurate paperwork can stop a shipment for days.Food exporters must follow:- FDA or FSSAI requirements

- HACCP guidelines

- packaging and hygiene regulations

- product testing standards

- phytosanitary rules

- temperature documentation

ECU360 simplifies compliance by allowing shippers to store and manage all required documents in one place, making it easier to stay prepared for inspections.

- Challenge 4: Preventing Contamination and Cargo Damage

Even in an FCL container, improper planning can lead to issues such as:- packaging failure

- condensation

- pests

- broken pallets

- odor transfer

- cargo leaning or collapsing

ECU360 supports shippers with container selection, loading guidance, and planning tools that help improve cargo integrity.

- Challenge 5: Seasonal Rate Fluctuations and Equipment Availability

The food and beverage sector is heavily influenced by seasons. Peak harvest seasons, holidays, and global demand shifts can increase freight costs and reduce container availability.ECU360 provides updated FCL rate visibility, helping companies adjust their shipping schedules based on seasonal market conditions and secure containers in advance.

3. Practical Solutions to Improve FCL Shipping in the F&B Sector

Food and beverage exporters can overcome major challenges by adopting structured processes and using digital tools available through ECU360.

- Solution 1: Strong Cold Chain Strategy

A reliable cold chain ensures product freshness from warehouse to destination.Key cold chain elements include:- pre-cooling containers

- selecting the correct reefer temperature

- monitoring humidity

- using proper ventilation

- reducing waiting time at the port

ECU360 helps shippers plan these details by showing shipping schedules, transit times, and container availability.

- Solution 2: Proper Packaging and Palletization

Correct packaging protects products from moisture, temperature, and physical damage.Best practices include:- using food-grade materials

- shrink wrapping pallets tightly

- keeping pallet height within limits

- distributing weight evenly

- using moisture absorbers

With ECU360, businesses can plan container loading efficiently, ensuring products are secured during long ocean journeys.

- Solution 3: Better Visibility for Shipment Tracking

Visibility is one of the biggest advantages of using ECU360. Shippers get real-time updates on:- container gate-in

- vessel departure and arrival

- transshipment

- estimated delivery times

- route changes or delays

This visibility helps companies coordinate with warehouses, customs, distributors, and buyers more smoothly.

- Solution 4: Route Optimization and Intelligent Scheduling

Food and beverage shipments are highly time-sensitive. ECU360 provides various sailing schedules with estimated transit times, allowing businesses to choose reliable routes that reduce delays and protect product quality. - Solution 5: Digital Documentation Management

Manual paperwork increases the chance of mistakes. ECU360 centralizes all documents, making it easier to upload, manage, and share documents with customs brokers, freight forwarders, or partners. - Solution 6: Better Cost Planning and Rate Comparison

Freight costs vary due to seasonality, demand, equipment shortages, and global logistics conditions. ECU360 offers transparent pricing, helping businesses compare rates and choose cost-effective options without compromising safety. - Solution 7: Warehouse-to-Port Process Coordination

Timely coordination ensures the cold chain remains intact up to the port.ECU360 helps shippers manage:- container pickup

- port gate-in timing

- stuffing schedules

- documentation readiness

This reduces idle time, prevents temperature fluctuations, and improves overall efficiency.

4. How ECU360 Strengthens the Food & Beverage Supply Chain with FCL Shipping

When FCL shipping is paired with ECU360’s digital logistics capabilities, the entire supply chain becomes more transparent, controlled, and predictable.

Shippers benefit from:

- stronger cold chain management

- better compliance

- fewer delays

- real-time tracking

- optimized costs

- smarter route decisions

- improved packaging planning

- reduced product loss

- easier communication with logistics partners

With every process connected through one platform, food and beverage companies can focus on quality, consistency, and global expansion.

Final Thoughts

The food and beverage sector cannot afford lapses in temperature control, documentation, or timing. FCL shipping provides the safety, space, and stability required for bulk food shipments, but its success depends on proper planning and execution. With the support of ECU360, companies can simplify container booking, manage documents efficiently, access transparent rates, and track shipments in real time.

This digital approach not only reduces risks but also strengthens the overall supply chain, ensuring that food and beverage products reach global markets safely, efficiently, and in the best possible condition.

Like

Comments