Electronics & Technology: Ensuring Safe FCL Shipping Across Borders

Electronics and technology products—from smartphones, laptops, and computer components to smart devices and accessories—are among the most valuable and fragile cargo in international trade. Because of their sensitivity to handling, moisture, temperature changes, and security risks, shipping these items demands extra care, precise documentation, and strict logistics planning.

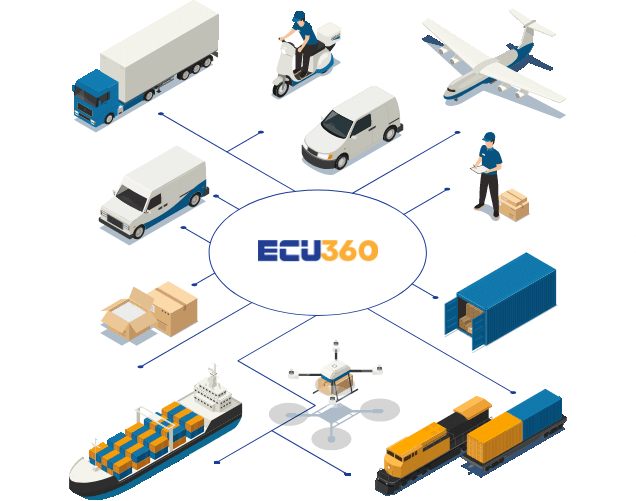

For many businesses, FCL (Full Container Load) shipping offers the safest and most efficient way to transport electronics across borders. When managed properly, FCL provides dedicated container space, reduced handling, and strong control over packaging, transit conditions, and compliance. ECU 360 supports this process end-to-end, helping exporters and importers navigate complex global logistics with confidence.

In this article, we present why FCL is often the best choice for electronics & technology shipments, what risks exist, and how businesses can prepare for safe, compliant, and cost-effective cross-border transport.

1. Why FCL Shipping Works Best for Technology Products

- Dedicated Container Space Reduces Risk

With FCL shipping, an entire container is assigned to one shipper. This means electronic goods are not mixed with other cargo—no risk of contact with chemicals, heavy machinery, or moisture-prone products. For sensitive devices, that isolation is critical to prevent damage or static issues. - Reduced Handling — Fewer Touchpoints

Because no consolidation or deconsolidation is needed, the container goes directly from origin to destination, minimizing loading/unloading cycles. This decreases the chance of mishandling—especially important for fragile electronics. - Better Control Over Packaging, Temperature & Humidity

Electronic components can be sensitive to humidity and temperature swings. In an FCL container, shippers can ensure proper packaging (anti-static bags, moisture barriers, sealed cartons) and, if required, use climate-controlled containers to prevent condensation or overheating. - More Consistent Insurance and Compliance

High-value electronics require accurate documentation, customs clearance, and often insurance. FCL shipments make it simpler to manage packing lists, serial numbers, commercial invoices, and certificates. This reduces customs-related delays and ensures smoother import/export compliance. - Cost Efficiency for Bulk Shipments

For large shipments—such as a full container of devices or components—FCL is often more economical than multiple smaller packages or air freight, especially for long-distance cross-border routes.

2. Common Risks and Challenges When Shipping Electronics Internationally

Even with the benefits of FCL, shipping electronics globally involves certain risks. Recognizing and planning for these helps ensure safe transit.

- Risk 1: Damage due to Impact, Moisture, or Static

Electronics are fragile. Rough handling, shifting during transit, or exposure to humidity can damage delicate components. Static electricity can also destroy electronic boards. - Risk 2: Temperature & Humidity Fluctuations

Ports, ships, or warehouses may expose cargo to extremes of temperature or damp conditions. Without careful packaging or humidity control, moisture can corrode circuits or damage screens. - Risk 3: Theft or Tampering

High-value cargo becomes a target during transit or at ports. Shared containers or improper sealing increase the risk of pilferage. - Risk 4: Customs Delays & Compliance Issues

Electronics often have strict import/export regulations. Incorrect documentation, missing HS codes, or compliance failures may lead to shipment holds, fines, or rejection. - Risk 5: Complex Tracking & Inventory Management

For shipments with many SKUs, serial numbers, or batches, maintaining accurate records is crucial. Mistakes complicate warranty claims, stock management, and customer satisfaction. - Risk 6: High Insurance Costs if Shipping Conditions Aren’t Controlled

Insurance premiums and liability increase if cargo is exposed to higher risk—especially when shipping high-value electronics across long routes without container control.

3. How to Ensure Safe and Efficient FCL Shipping for Electronics

To minimize risk and ensure safe delivery, businesses shipping electronics should follow a set of best practices. When coordinated with ECU 360, these practices become much easier to implement.

- Best Practice 1: Use Professional Packaging & Palletization

Use anti-static and moisture-resistant packaging (anti-static bags, sealed cartons, desiccants).- Wrap cartons in shrink-wrap or stretch-wrap to prevent shifting.

- Use sturdy pallets with load‑secure strapping.

- Label each carton with SKU, weight, handling instructions, and orientation.

Proper packaging and wrapping prevent movement, moisture ingress, and static damage throughout transit.

- Best Practice 2: Consider Climate‑Controlled or Temperature‑Monitored Containers

For sensitive electronics, climate-controlled containers or humidity-monitored containers help avoid condensation, overheating, or cold‑temperature damage. ECU 360 provides access to container options and logistics planning for such requirements. - Best Practice 3: Plan Documentation and Regulatory Compliance Early

Prepare and verify:- Commercial invoices with correct HS codes

- Packing lists detailing number of units, serial numbers/SKUs, weights and volumes

- Export/import licenses (where required)

- Certificates of origin or compliance (if requested by importing country)

- Insurance documentation

ECU 360 lets shippers manage and upload all required documents well before departure to avoid customs delays.

- Best Practice 4: Secure Container Sealing and Use Tamper‑Proof Methods

Once the container is loaded, apply a high-security seal, record the seal number, and note its condition. Document the condition photographically if possible. Sealing helps protect against theft or tampering during transit. - Best Practice 5: Choose Reliable Shipping Routes & Carriers

Select carriers and routes with:- Direct or minimal‑transshipment sailings

- Good port performance records

- Fast processing at departure and arrival ports

ECU 360 helps compare carriers and routes, offering transparency on transit times and service quality—key for electronics shipments.

- Best Practice 6: Manage Insurance and Risk Coverage Properly

High-value electronics demand good insurance coverage. Declare full cargo value, ensure packaging details are listed, and keep records of container condition and transit history. This helps expedite insurance claims if damage occurs. - Best Practice 7: Track Shipments Continuously

Use tracking to:- Monitor container location

- Track estimated time of arrival (ETA)

- Monitor environmental conditions (if available)

- Alert for delays or route changes

With ECU 360’s tracking and milestone notifications, businesses can react quickly and coordinate with importers or warehouses.

- Best Practice 8: Plan Warehouse Readiness & Handling at Destination

Once the shipment arrives:- Prepare secure storage for electronics

- Keep warehouse humidity under control

- Use anti-static mats and proper handling procedures

- Check carton condition before unloading

- Verify serial numbers against packing lists

Proper warehouse handling reduces post-shipment damage and ensures accurate inventory.

4. How ECU 360 Enhances Global Electronics Distribution via FCL Shipping

Using FCL shipping for electronics becomes significantly more manageable and secure when coordinated via ECU 360. Here’s how ECU 360 supports businesses:

- Clear container booking options — including standard and climate‑controlled containers

- Transparent pricing and freight cost breakdowns, helping businesses assess cost vs value

- Document management — upload and store all shipping, customs, compliance, and insurance documents in one place

- Real‑time shipment tracking and milestone alerts — from loading to port transit to arrival

- Route and carrier comparison — enabling shippers to choose fast, reliable services for sensitive cargo

- Support for bulk shipments and large‑volume orders, reducing per-unit cost and maximizing container utilization

With all logistics handled through a single, organized workflow, businesses can focus on product quality, sales, and distribution rather than worrying about shipping complexities.

5. Example Use-Cases Where Safe FCL Shipping Matters

- Case 1: Exporting High‑End Consumer Electronics

A company shipping smartphones in bulk needs safe packaging, humidity control, secure container sealing, and fast transit. FCL avoids multiple handling, and ECU 360 makes sure scheduling and compliance are smooth. - Case 2: Shipping Computer Components to Distribution Centers

Fragile motherboards, GPUs, and RAM sticks require anti-static packaging and controlled handling. FCL with proper packing and container selection minimizes risk. ECU 360’s documentation and tracking ensure safe delivery. - Case 3: Global Distribution of Smart Home Devices

With multiple SKUs, high value per unit, and sensitive electronics, smart devices need reliable transport. FCL ensures isolation from mixed cargo, and ECU 360 supports bulk shipment scheduling, tracking, and compliance — ideal for global distribution.

6. Conclusion: FCL Shipping + ECU 360 = Safe & Reliable Tech Logistics

Shipping electronics and technology products across borders involves multiple risks — from moisture damage to static shock, from delays to theft, and from documentation issues to complex customs regulations. For high-value, fragile, or bulk electronics cargo, FCL shipping offers the best mix of safety, cost-efficiency, and control.

When combined with the structured, transparent, and well-supported logistics workflow provided by ECU 360, businesses get access to: secure container bookings, appropriate container types, seamless documentation, real-time tracking, and reliable port-to-port logistics — making global electronics distribution much simpler and safer.

For electronics exporters, tech brands, and global distributors, this means fewer shipment errors, lower damage rates, timely deliveries, and stronger supply chain resilience.

Like

Comments