How ‘Chaos’ In the Shipping Industry Can Create Opportunities

You’ve heard enough to recognise it coming from a nautical mile away – the ‘shipping chaos’. But is there a way to improve the situation? To find out, let’s understand why we’re in this whirlpool.

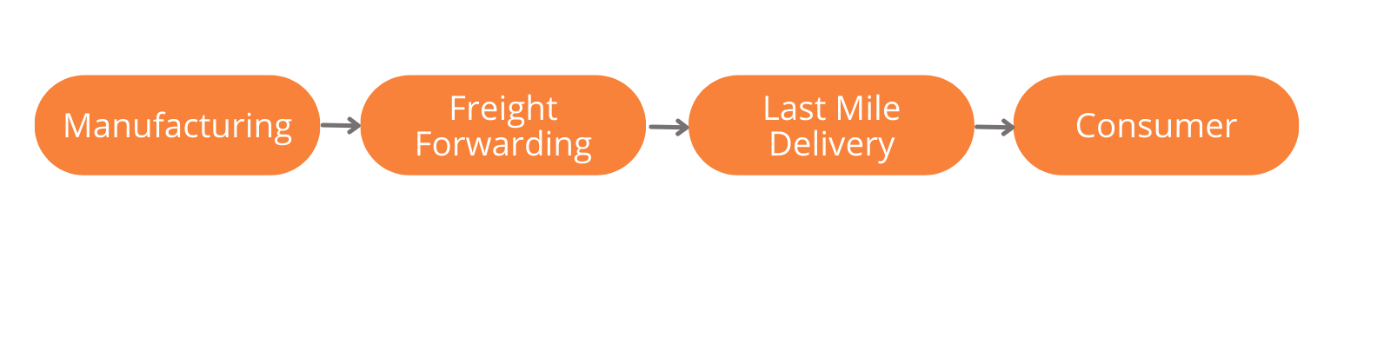

Level 1: Pre Crisis

Before the pandemic, supply chains worldwide moved at an almost smooth pace. Manufacturers would produce goods from raw materials and send finished products for distribution. That was most of it.

After the pandemic, things started to look different.

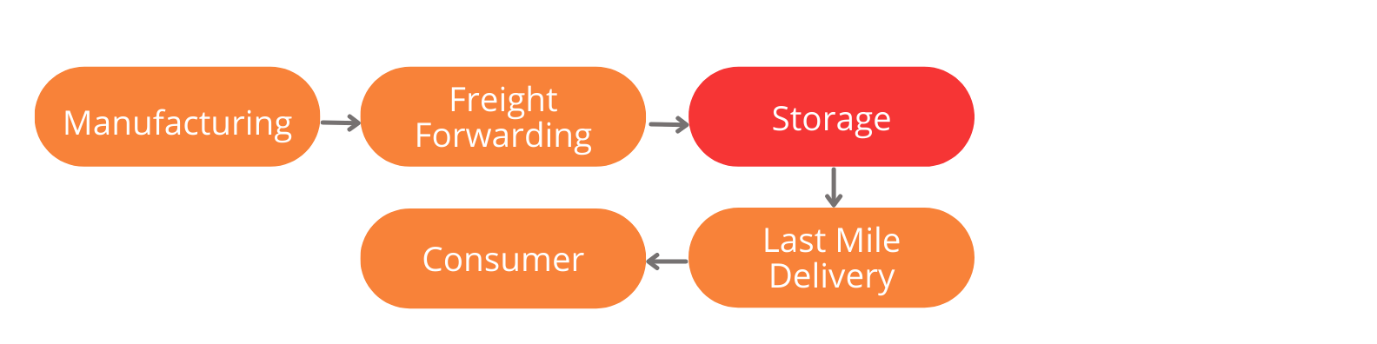

Level 2: Ecommerce Expansion & Container Woes

Because people became comfortable with digital technology during the pandemic, they increasingly ordered online orders. eCommerce grew, and therefore, manufacturers had to produce more goods for distribution. Here’s a significant problem, however. There weren’t enough people at ports to process these goods. Because the pandemic was still raging, not all countries eased restrictions for work and travel, and unfortunately, the world lost people to COVID19.

What followed? The container pile-up.

Ships had no choice but to wait at ports for several weeks. But it didn’t end there. Once ports processed their cargo, there weren’t enough truckers to complete last-mile delivery.

Moreover, as trade grew over the last few decades, ships also grew in numbers and size. Larger ships carry more cargo than older ones in a single trip. Unfortunately, port capacity didn’t grow that much, and very few dock these humongous ships.

Vessels waiting to unload cargo off California’s coast (Source)

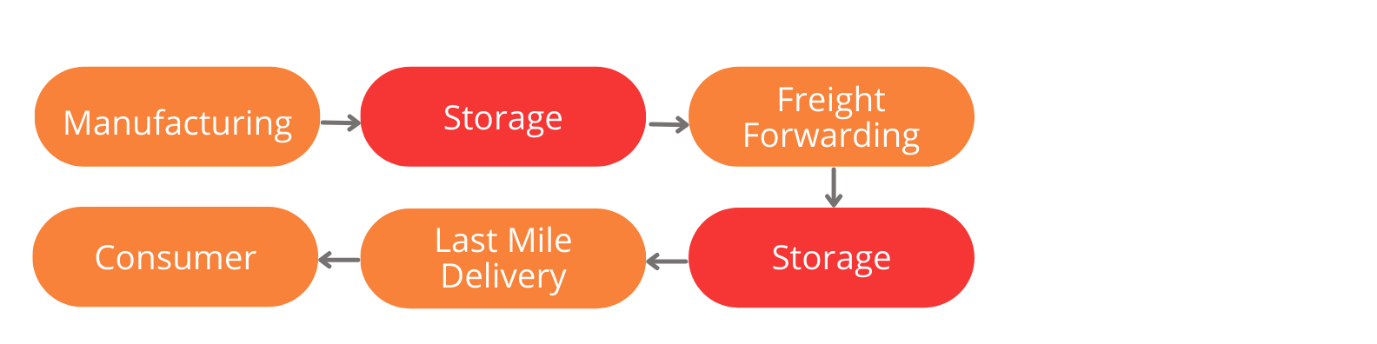

Level 3: Ecommerce Expansion, Container Woes, Raw Material Pile-up

While ships waited to unload, truckers waited to load them for final delivery, manufacturers kept receiving more orders and ordered more raw materials to keep up. Meanwhile, producers couldn’t load finished goods faster with a workforce shortage. Ships left port with empty containers because products didn’t reach them in time. Slow processing also delayed raw material supply, and by the time it arrived, consumers cancelled orders due to long waiting times.

The result – raw materials and finished goods started piling up at the warehouse and port.

And lastly, global interdependence – the icing on the cake of the supply chain success story so far – caused the most significant problems. You saw the cascading effects of China’s closure of ports. But amidst all this chaos, you’re missing something important.

There are new opportunities

“In the midst of every crisis, lies great opportunity.” – Albert Einstein

And one of the most brilliant visionaries to have walked on Earth isn’t wrong.

Despite multiple issues, global freight forwarding continued operations, shifting focus from cost-effectiveness to flexibility and resilience. That’s where you’ll find new opportunities.

Conventionally, freight forwarding runs through excel sheets, emails and phone calls to people across the chain, with limited visibility on the cargo’s location. But now, businesses want to leverage data generated through logistics activities to make the process more transparent.

If you’re wondering about the hubbub surrounding data, liken it to knowledge. By harnessing this knowledge, industries can understand how well they perform today and predict a better tomorrow. Only if it was that easy. You need to sort through large data sets, find what’s relevant and perform actions that bring results.

Enter digitisation – mainly Artificial Intelligence (AI), Big Data, Cloud Computing, Blockchain, Robotics and Automation. ECU360’s solutions use technology to make the freight forwarding process unified. You don’t have to view multiple emails, browse through huge excel sheets, or scour numerous physical documents. Instead, you have all the information in one place, making it seamless.

Technology giants worldwide are also introducing supply chain-specific digital solutions like Microsoft’s Dynamics 365 Supply Chain Insights and Amazon’s Forecast and SageMaker. Google and Oracle offer products, too. Such is the impact that over 41% of industry leaders are speeding up technology adoption in freight forwarding capabilities.

But integrating technology is not just an industry-level activity. Countries are also investing in port infrastructure, focusing on digital technologies. Specifically, emerging markets like China and India are taking the cake for business competitiveness and digital readiness.

Some nations are also dabbling in self-driving vehicles, battery-powered trains, and robotics. These innovations will eventually reduce reliance on the human workforce to a certain extent, which has been overdue now.

Concept:Robots handling cargo (Source)

That said, people will always be at the centre of logistics, and businesses still need several workers to oversee processes. Therefore, improved workforce hiring, training, upskilling and benefits will play a key role in improving the state of the supply chain.

All of this works great, but not without sustainability considerations, taking better care of the planet and people. You’ll be glad to know, industry participants are moving towards greener alternatives to make this possible.

The last mile

Getting your cargo from one corner of the world to the other may seem like a long way now. But at the last mile of this shipping chaos lie new opportunities to improve the logistics process from start to finish.

Ultimately, these opportunities allow us to break down today’s global yet disjointed supply chain, understand its core problems and find solutions for creating a more inclusive and connected channel.

Like

Comments